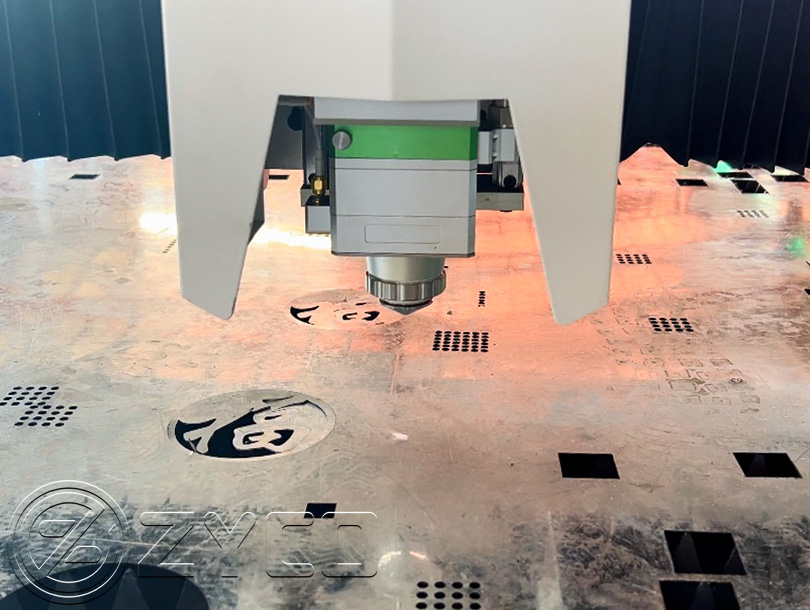

Grande sconto Macchina professionale automatica per il taglio laser a fibra idraulica CNC da 6000 W per tagli pesanti

Questa macchina per il taglio laser è dotata di un sistema di controllo dell'aria ottimizzato ed è dotata di componenti pneumatici di fama internazionale, migliorando significativamente la sua efficienza economica. Utilizza inoltre componenti principali di marchi nazionali leader come il sistema Bochu e il laser Chuangxin, garantendo doppiamente stabilità operativa e prestazioni superiori.

Ordine (MOQ) :

1Origine del prodotto :

Nanjing,Jiangsu,ChinaPeso :

3000kgTempo di garanzia :

2 yearsAutomazione :

AutomaticPunti di forza chiave :

High precision, high speed, save material, save laborZYCO

1. L'innovativo design della struttura cava, abbinato a un motivo interno a squame di pesce, migliora notevolmente la sicurezza antincendio dell'apparecchiatura.

2. L'intero telaio è trattato con un processo di ricottura ad alta temperatura, combinato con sabbiatura ad alta velocità e tecnologia di riduzione delle sollecitazioni per eliminare efficacemente le sollecitazioni interne, garantendo che l'attrezzatura non si deformi durante l'uso a lungo termine e mantenga la stabilità morfologica per oltre 20 anni.

3. L'attrezzatura offre eccellenti prestazioni dinamiche, tra cui funzionamento ad alta velocità, risposta dinamica eccezionale e rapida accelerazione.

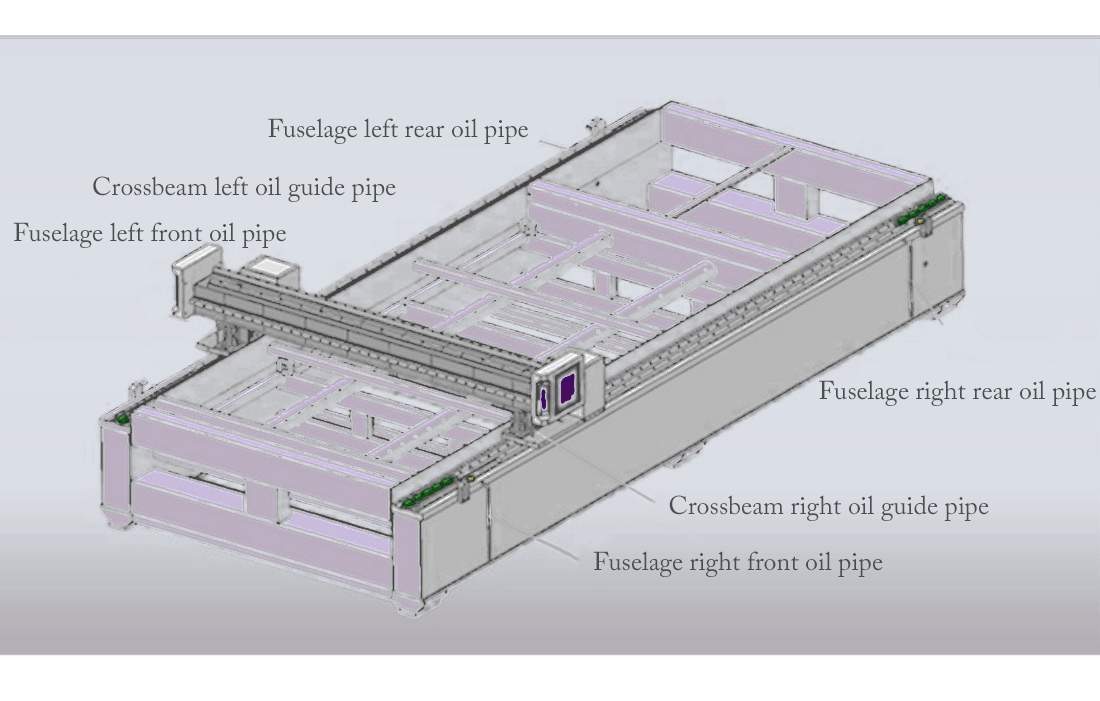

Visualizzazione della struttura interna

Per specifiche più dettagliate, non esitate a contattarci.

Struttura di saldatura del letto

Sistema di lubrificazione originale della macchina utensile

--La precisione della macchina utensile deriva dalla cremagliera e dalla guida lineare.

--Cremagliera: Determina la precisione.

--Guida lineare: determina la direzione.

Generalmente, la lubrificazione convenzionale dei produttori di macchine utensili è di una volta ogni 4 ore. Non esiste un sistema a circuito chiuso nel circuito dell'olio e l'olio tende a traboccare e gocciolare sulla piastra, compromettendo l'effetto di taglio. Tuttavia, il nostro sistema a circuito chiuso originale e migliorato consente la lubrificazione una volta ogni mezz'ora, riducendo i tempi di lubrificazione, aumentando la frequenza di lubrificazione, aumentando il numero di cicli di lubrificazione per cremagliere e guide lineari, riducendo l'usura di cremagliere e guide, migliorando la precisione e prolungando la durata della macchina utensile.

Parametri del prodotto

| 1. Parametri del processo di taglio dell'acciaio inossidabile | Lunghezza focale del collimatore della testa di taglio (mm): 100 (1kW-/15kW) Lunghezza focale della lente di messa a fuoco della testa di taglio (mm): 125 (≤2KW); 150 (3KW, 4KW); 200 (≥6KW) | ||||||||

Potenza/velocità laser di taglio (m/min (w) /Spessore della tavola (mn) | 1000 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 15000 |

| 1 | 20-22 | 45-50 | 60-70 | 40-45 | 45-50 | 47-55 | 50-55 | 54-58 | 60-65 |

| 2 | 6,5-7,0 | 13-15 | 22-27 | 20-25 | 30-35 | 34-39 | 39-42 | 41-46 | 44-49 |

| 3 | 2,5-3,0 | 5.0-6.0 | 8.0-10 | 11-13 | 17-20 | 21-25 | 23-29 | 30-33 | 32-37 |

| 4 | 1.2-1.4 | 3-3,5 | 6.0~70 | 6.5-7 | 13-15 | 18-21 | 19-23 | 22-26 | 24-28 |

| 6 | 0,9-1,2 | 2.1-2.6 | 2.5-3 | 6-6,5 | 7-8,5 | 10-12 | 16 | 16-18 | |

| 8 | 0,4-0,6 | 0,85-1,2 | 1,6-1,8 | 3.8-4.2 | 4.1-4.8 | 7-7,5 | 10 | 12-14 | |

| 10 | 0,2-0,5 | 0,6~0,8 | 0,8-0,9 | 1.6-2.1 | 2.8-3.2 | 5-5.8 | 6-7 | 7-9 | |

| 12 | 0,5-0,6 | 0,7-0,75 | 1.1-1.4 | 1,6-2,0 | 3.3-3.7 | 4-4.5 | 4.5-5 | ||

| 14 | 0,5-0,55 | 0,9-1,1 | 1,3-1,55 | 1.7-2.1 | 2.1-2.8 | 2,5-3,1 | |||

| 16 | 0,6-0,8 | 1.1-1.3 | 1.6-1.7 | 1,8-2,3 | 2-2,5 | ||||

| 18 | 0,5-0,65 | 0,7-0,82 | 1.1-1.25 | 1.2-1.4 | 1,65-1,8 | ||||

| 20 | 0,4-0,5 | 0.65-0,75 | 0,8-1,1 | 1,3-1,6 | 1,4-1,8 | ||||

| 25 | 0,4-0,5 | 0,45-0,5 | 0,55-0,65 | 0,6-0,7 | |||||

| 30 | 0,3-0,33 | 0,35-0,4 | 0,45-0,55 | 0,45-0,6 | |||||

| 35 | 0,22-0,25 | 0,3-0,45 | 0,3-0,4 | ||||||

| 40 | 0,25-0,34 | 0,2-0,35 | |||||||

| 45 | 0,16-0,23 | 0,16-025 | |||||||

| 50 | 0,12-02 | ||||||||

| Nota: I caratteri verdi sono dati di taglio stabili nella maggior parte delle condizioni di produzione; i caratteri blu sono dati di taglio che potrebbero essere ottenuti in condizioni di produzione migliori; i caratteri rossi sono dati di taglio estremi ottenuti in condizioni di laboratorio. | |||||||||

| 2. Parametri del processo di taglio dell'acciaio al carbonio | Lunghezza focale del collimatore della testa di taglio (mm): 100 (1kW-/15kW) Lunghezza focale della lente di messa a fuoco della testa di taglio (mm): 125 (≤2KW); 150 (3KW, 4KW); 200 (≥=6KW) | |||||||||

| Potenza/velocità laser di taglio (m/min(w) /Spessore della tavola (mm) | 1000 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| 1 | 22-25 | 42-47 | 48-55 | 42-45 | 45-48 | 46-52 | 49-55 | 50-58 | 55-60 | |

| 2 | 5-6 | 5-6 | 5-6 | 18-21 | 29-35 | 32-37 | 34-39 | 35-41 | 36-42 | |

| 3 | 2,8-3,0 | 4.0-4.5 | 3,5-4,3 | 4-4.5 | 4-5 | 4-5 | 4-5 | 4-5 | 26-31 | |

| 4 | 2.2-2.4 | 3,6-4,0 | 3.2-4 | 3.5-4 | 3.5-4 | 3.5-4 | 3.5-4 | 3.5-4 | 19-22 | |

| 6 | 1,3-1,6 | 2.2-2.7 | 2-2,5 | 2.4-2.7 | 2.8-3.3 | 2.8-3.1 | 2.8-3.2 | 2.8-3.3 | 14-17 | |

| 8 | 1.0-1.2 | 1,4-1,8 | 1,8-2,4 | 2-2.3 | 2.1-2.4 | 2.1-2.45 | 2.1-2.45 | 2.1-2.6 | 2.1-2.6 | |

| 10 | 0,8-1,0 | 1.1-1.5 | 1,4-1,8 | 1.8-2 | 2-2.2 | 2.0-2.3 | 2.1-2.5 | 2.1-2.5 | 2.1-2.6 | |

| 12 | 0,96-1,2 | 0.9-1.1 | 1.5-1.6 | 1,9-2,0 | 1,9-2,0 | 1.9-2.1 | 1.9-2.1 | 1,85-2,1 | ||

| 14 | 0,9-1,1 | 0,75-0,9 | 1.2-1.4 | 1,5-1,7 | 1,6-1,75 | 1,7-1,85 | 1,66-1,75 | 1.7-18 | ||

| 16 | 0,7-0,8 | 0,7-0,8 | 1-1.1 | 1,25-1,35 | 1.45-1.6 | 1,5-1,6 | 1,55-1,65 | 1.6-1.7 | ||

| 18 | 0,6-0,7 | 0,6-0,8 | 0,8-0,95 | 1.15-1.3 | 1.2-1.45 | 1,35-1,4 | 1,4-1,55 | 1,5-1.6 | ||

| 20 | 0,5-0,6 | 0,6-0,75 | 0,6-0,7 | 0,9-1,0 | 1.0-1.2 | 1.1-1.3 | 12-1.3- | 1,4-1,5 | ||

| 25 | 0,5-0,55 | 0,45-0,55 | 0,5-0,55 | 0,5-0,6 | 0,65-0,7 | 0,65-0,7 | 0,8-1,0 | |||

| 30 | 0,3-0,35 | 0,4-0,42 | 0,4-0,45 | 0,64-0,8 | ||||||

| 35 | 0,25-0.3 | 0,37-0,38 | 0,25-0,28 | 0,4 | ||||||

| 40 | 0,25-0,26 | 0,2-0,26 | 0,32 | |||||||

| 45 | 0,18-0,22 | 0,25 | ||||||||

| 50 | 0,15 | 0,18 | ||||||||

| Nota: 1) Il carattere verde sono i dati di taglio stabili nella maggior parte delle condizioni di produzione; il carattere blu sono i dati di taglio che possono essere ottenuti in alcune migliori condizioni di produzione; il carattere rosso sono i dati di taglio limite ottenuti in condizioni di laboratorio. 2) I dati sottolineati sono i dati di taglio dell'azoto. | ||||||||||

Partner

Foto dei clienti

Certificato d'onore

Lascia il tuo indirizzo e -mail e i requisiti, il nostro team di vendita professionale svilupperà la soluzione più adatta per te.

Copyright

© 2026 Nanjing Zyco CNC Machinery Co., Ltd. Tutti i diritti riservati

.

RETE SUPPORTATA

RETE SUPPORTATA