Nel campo della lavorazione della lamiera, le piegatrici sono le attrezzature principali per la modellazione dei contorni del prodotto e la loro precisione influisce direttamente sulla qualità dei prodotti finiti. macchine piegatrici si basano sulla marcatura manuale e sul posizionamento meccanico dei blocchi, operazioni complesse e facilmente limitate dall'esperienza. Con la maturazione della tecnologia laser, il processo di allineamento laser è stato introdotto nel processo di piegatura, diventando una svolta fondamentale per il miglioramento dell'efficienza e della precisione. Questo articolo ne analizza approfonditamente i principi tecnici, gli scenari applicativi e le prospettive future.

ⅠPrincipio di funzionamento della tecnologia di allineamento laser

Il sistema di allineamento laser integra trasmettitori laser ad alta precisione e sensori ottici per creare una rete di calibrazione dinamica in tempo reale. Il suo processo principale è il seguente:

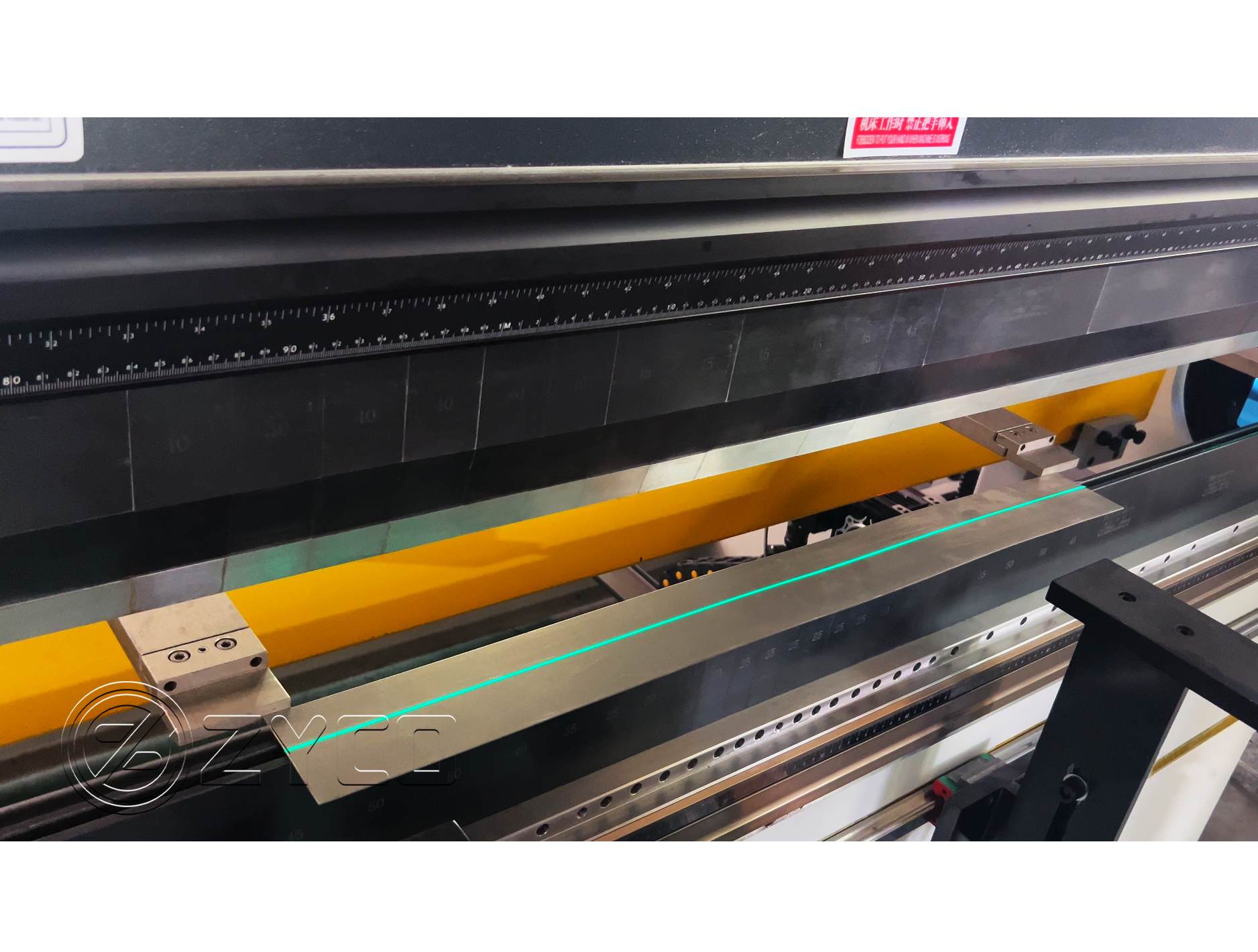

1. Posizionamento della proiezione laser: Proiettare linee laser visibili sul tavolo di lavoro della piegatrice per contrassegnare con precisione la posizione di piegatura del lamiera, sostituendo i tradizionali blocchi fisici.

2. Rilevamento laser: Per i prodotti piegati in lamiera, la rettilineità del prodotto può essere rilevata tramite linee laser.

ⅡVantaggi principali della tecnologia di allineamento laser

1. Salto di precisione: Elimina gli errori visivi manuali e riduce l'errore cumulativo della piegatura multi-passata complessa di oltre il 70%, particolarmente adatto per settori ad alta precisione come l'industria aerospaziale.

2. Incremento dell'efficienza: eliminando la marcatura manuale e i ripetuti passaggi di piegatura, riducendo del 50% i tempi di debug per il cambio stampo e adattandosi alla produzione flessibile di piccoli lotti e multi-varietà.

3. Ottimizzazione della collaborazione uomo-macchina: L'operatore monitora lo stato dell'allineamento in tempo reale tramite un'interfaccia visiva, riducendo il carico fisico e migliorando notevolmente la sicurezza.

4. Tracciabilità dei dati: Il sistema registra ogni parametro di piegatura, supporta l'ottimizzazione del processo e il monitoraggio della qualità, ed è conforme alla tendenza intelligente dell'Industria 4.0.

III. Scenari e casi applicativi tipici

- Produzione di componenti per autoveicoli: Dopo che un'azienda automobilistica ha adottato una piegatrice con allineamento laser, la consistenza della piegatura della staffa della cerniera della portiera è aumentata dall'89% al 99,5% e il tasso di scarto è diminuito del 40%.

- Lavorazione elettronica di precisione delle coperture: Per i gusci in acciaio inossidabile ultrasottili, il sistema laser raggiunge una regolazione fine a 0,1 mm per evitare graffi sulla superficie del materiale.

- Formatura efficiente di parti di forma speciale: Grazie alla libreria di percorsi laser preimpostati personalizzati, è possibile passare rapidamente a schemi di piegatura complessi, come quelli a U e a Z, per soddisfare i requisiti dell'ordine.

IV. Sfide tecniche e prospettive future

Attualmente, la tecnologia di allineamento laser presenta ancora difficoltà come l'interferenza di materiali altamente riflettenti e la calibrazione di più strati di sovrapposizione. Le direzioni di sviluppo future includono:

- Algoritmo adattivo AI: In combinazione con l'apprendimento automatico, identifica automaticamente le proprietà dei materiali e ottimizza i modelli di compensazione.

- Collaborazione tra dispositivi: Collegamento con macchine per il taglio laser e robot di saldatura per realizzare una linea di produzione digitale completa.

- Soluzione di divulgazione a basso costo: Sviluppare un sistema laser modulare compatto per aiutare le piccole e medie imprese ad aggiornare la propria tecnologia.

Conclusione

La tecnologia di allineamento laser ridefinisce i limiti di precisione del processo di piegatura e promuove la trasformazione della lavorazione dei metalli da "guidata dall'esperienza" a "guidata dai dati". Con l'avanzare della produzione intelligente, questa tecnologia diventerà un "occhio intelligente" indispensabile nelle officine di lavorazione della lamiera, iniettando energia cinetica duratura nella precisione industriale e nella produzione flessibile.

Lascia il tuo indirizzo e -mail e i requisiti, il nostro team di vendita professionale svilupperà la soluzione più adatta per te.

Copyright

© 2026 Nanjing Zyco CNC Machinery Co., Ltd. Tutti i diritti riservati

.

RETE SUPPORTATA

RETE SUPPORTATA